Join your fellow Montie Gear customers for a fun filled weekend camping at Troublesome Gap, NC. The event is free, but an RSVP is required. It all begins on May 26th. This is a family friendly event, so all are welcome. Please RSPV at http://troublesomegap.eventbrite.com

Check out the view from above the campsite. Click on the image below to see the video.

Don’t forget to RSVP at troublesomegap.eventbrite.com

Write a Review – Get an Awesome Coupon!

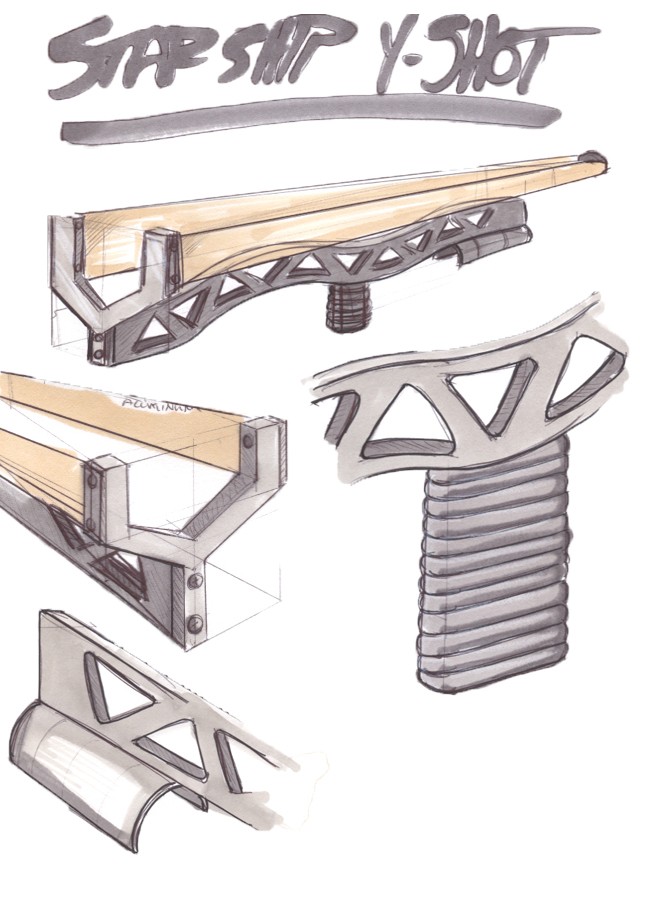

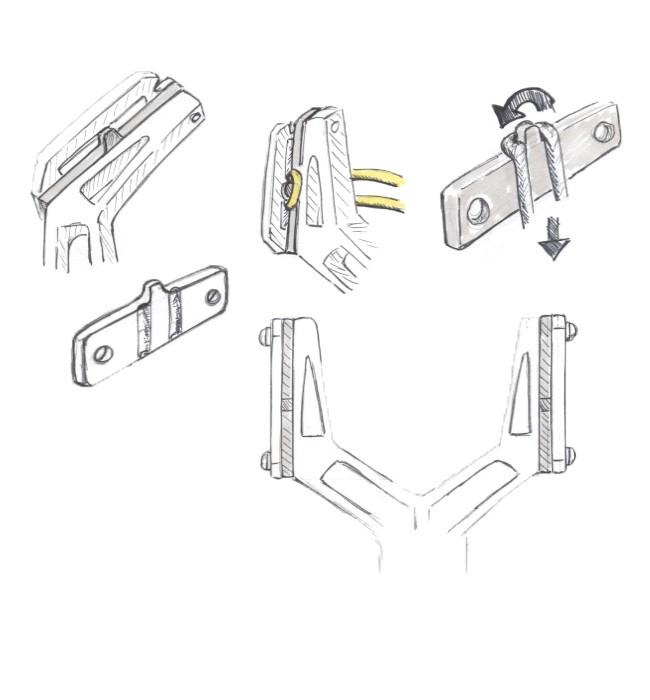

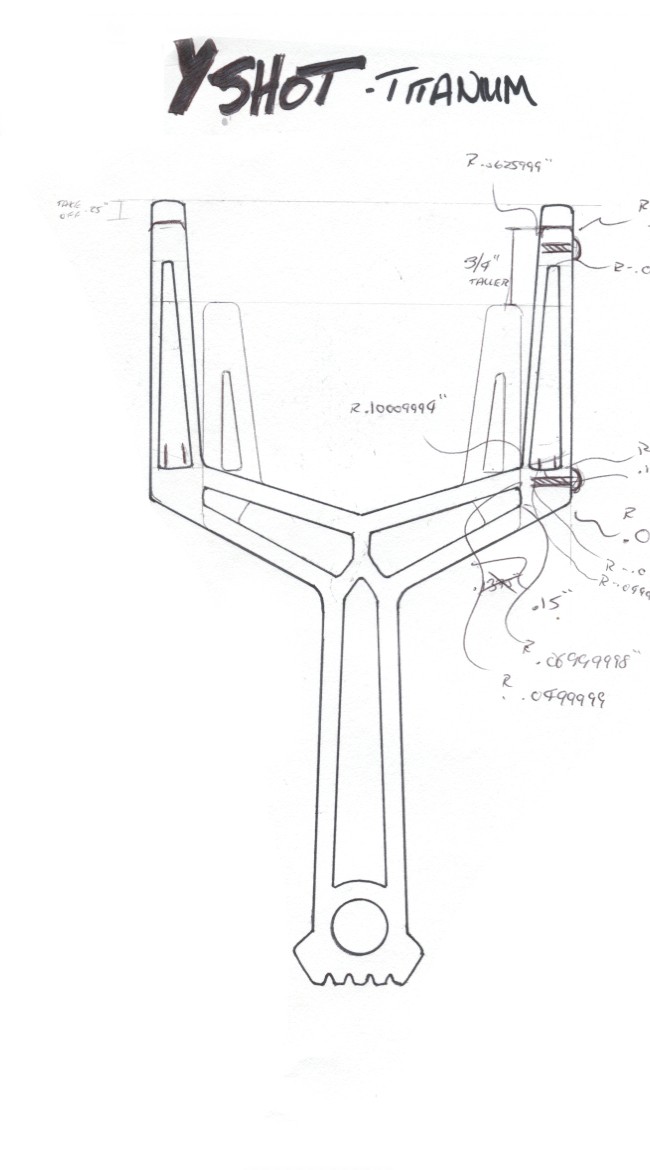

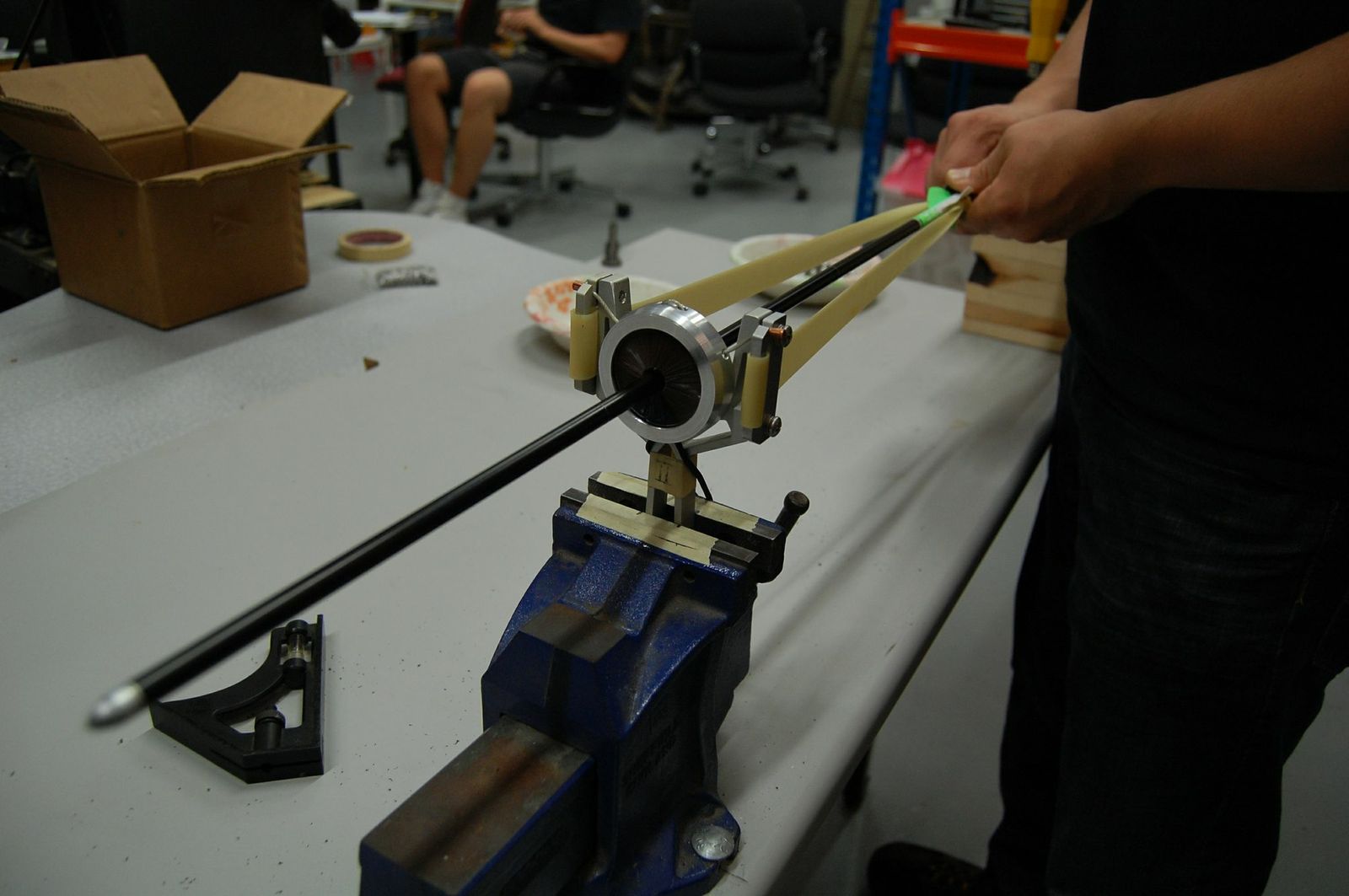

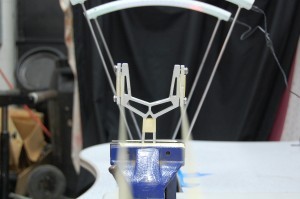

Do really like your Montie Gear slingshot, AR-Rest or other product? Help us tell the world about the Handmade, Heirloom Quality products that we make right here in NC!

Reviewing your Montie Gear product is a great way to give potential customers access to your opinion before they buy. We’ve streamlined the review process to make it quick and easy for you. Please a take a few minutes and review your Montie Gear products by going to www.montiegear.com, logging into your account, navigating to your favorite Montie Gear product at www.montiegear.com and then click on “Add Review”. Once your review is submitted, please email me at montie@montie.com and I’ll email a coupon code good for 25% off your next purchase!